In the field of engineering and construction, ensuring the durability and strength of materials is of paramount importance. When evaluating the quality of pipes, particularly American Standard pipes, we conduct a Tensile Test. This test aids in determining the strength of the pipes and assesses the adequacy of welds in welded pipes. Let us delve deeper into the mechanics of this testing method.

Understanding ASTM A53 Grade B Pipe:

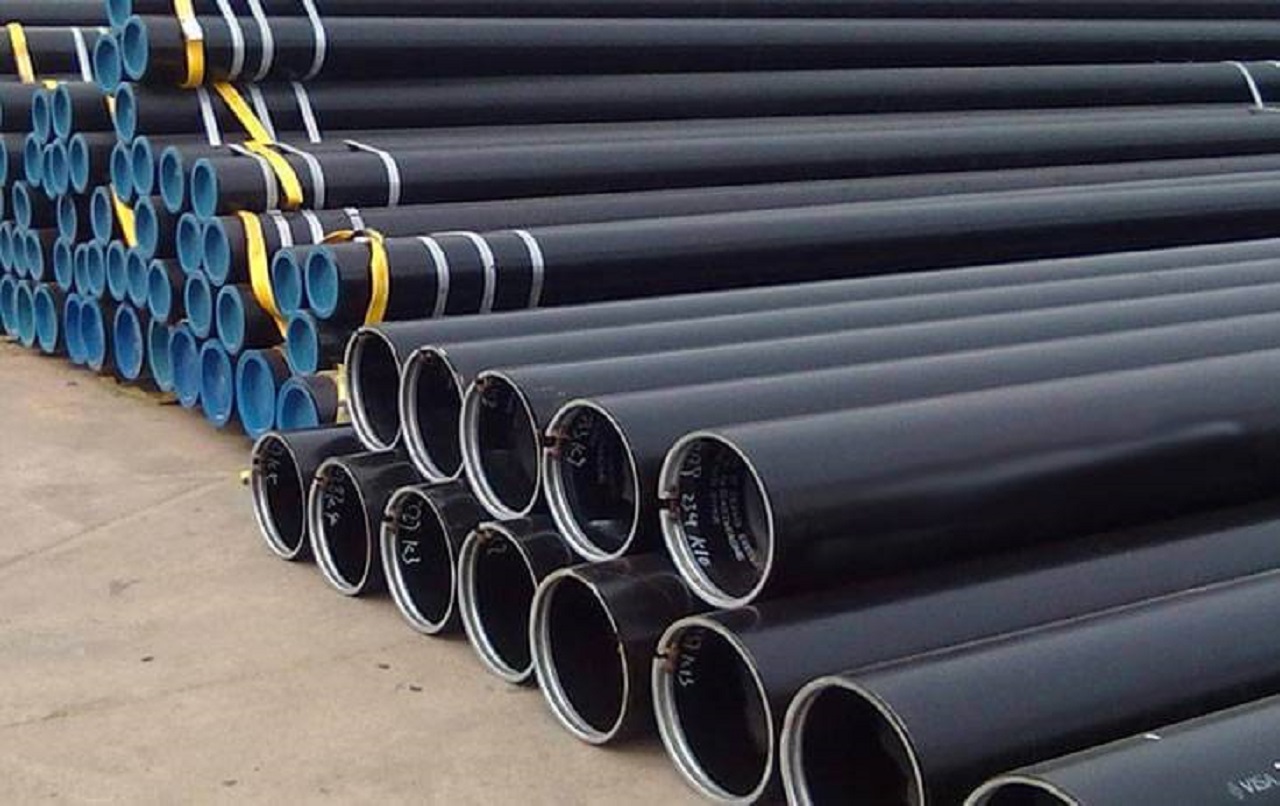

Before delving into the specifics of the Tensile Test, it’s imperative to grasp the significance of astm a53 gr b pipes. These pipes are widely utilized in various industrial applications, ranging from plumbing to structural frameworks. Known for their robustness and versatility, ASTM A53 Grade B pipes are crafted to withstand demanding conditions, making them a cornerstone in construction projects worldwide.

The Significance of Tensile Testing:

Tensile Testing serves as a foundation for evaluating the mechanical properties of materials, including pipes. This method involves subjecting a specimen of the material to controlled tension until it reaches its breaking point. By analyzing the resulting data, engineers gain crucial insights into the pipe’s tensile strength, yield strength, elongation, and other pertinent parameters. Through thorough analysis of these parameters, engineers can make informed decisions regarding the suitability of the material for its intended application and identify any potential weaknesses or areas for improvement in the manufacturing process.

Assessing Weld Strength:

Making sure the welds in pipes are strong is really important. According to ASTM A53 standards, the strength of the weld shouldn’t be weaker than the rest of the pipe. This means we have to carefully test the welds to make sure they’re strong enough. By checking both the pipe itself and the welds, engineers can make sure the joints are strong, which keeps the whole pipeline safe and sturdy.

The Tensile Testing Procedure:

Conducting a Tensile Test on pipes involves a meticulous process. A representative specimen is carefully selected, prepared, and mounted onto a Tensile Testing machine. The machine applies a gradually increasing tensile force to the specimen until it fractures. Throughout this process, precise measurements are taken, and data is recorded to analyze the material’s behavior under tension.

Interpreting the Results:

Once the Tensile Test is completed, engineers analyze the gathered data to draw meaningful conclusions about the pipe’s mechanical properties. Key parameters such as ultimate tensile strength, yield strength, and elongation are scrutinized to ensure compliance with ASTM standards. Moreover, special attention is paid to the weld region, verifying that its strength aligns with or exceeds that of the pipe body.

Conclusion:

The reliability of materials such as American Standard pipes is non-negotiable. Through Tensile Testing, engineers gain invaluable insights into the mechanical properties of these pipes, ensuring they meet stringent quality standards. Furthermore, this testing method serves as a vital tool for assessing weld strength in welded pipes, thereby guaranteeing the structural integrity of vital infrastructure projects. As we continue to push the boundaries of innovation, Tensile Testing remains an indispensable tool in our quest for excellence and reliability in engineering.